In the modern production base of Hightop Group, the birth of every construction machinery requires a journey of continuous improvement in manufacturing. From design to production, the seven rigorous production processes are interlinked, jointly building a solid foundation for the reliable quality of Hightop products.

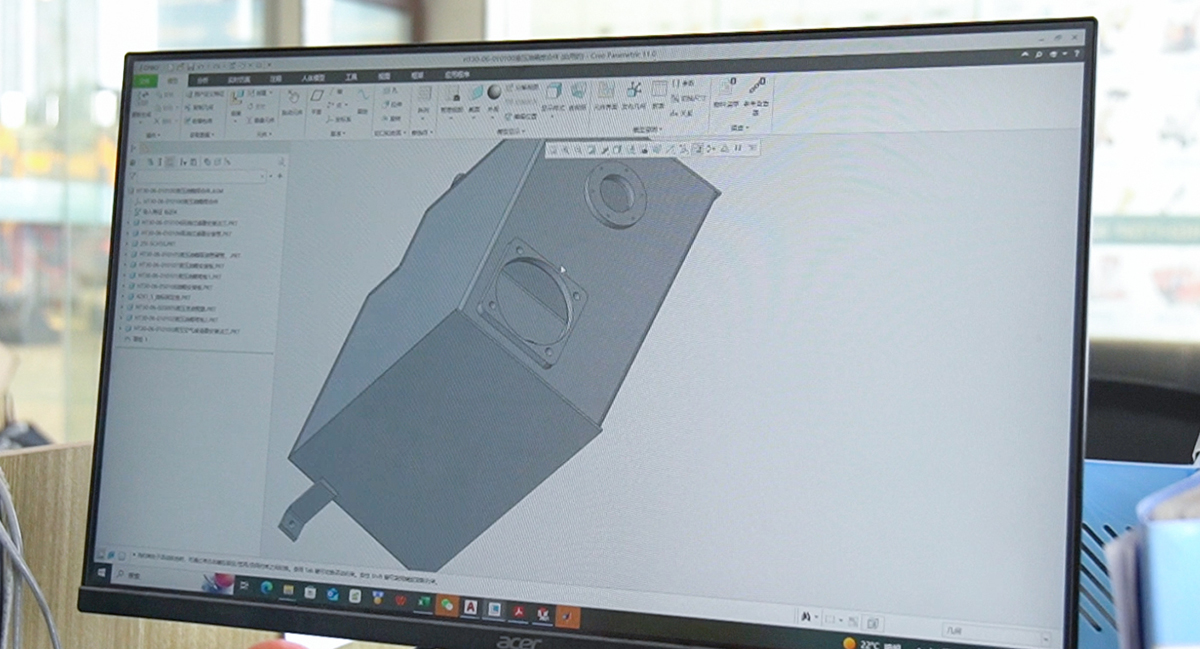

Process 1: Innovative Design

Each device begins with a rigorous design blueprint. The Hightop engineering team uses advanced CAD/CAM design systems to develop and innovate products based on market demand, providing precise technical guidance and data support for subsequent production.

Beyond conventional structural design, Hightop’s R&D engineers also focus on performance optimization, ergonomics, energy efficiency, and component durability. Before any product enters the machining stage, it goes through digital simulation analysis such as stress testing, load distribution optimization, dynamic modeling, and structural strength evaluation. These steps help to identify potential weaknesses, improve structural arrangements, and confirm the feasibility of manufacturing.

Market demand research is also integrated into the design phase. Engineers collect real-world feedback from global users—including construction contractors, agricultural operators, equipment leasing companies, and overseas distributors—to guide design upgrades. This ensures that each new model or technical iteration directly responds to end-user needs such as narrow-area maneuverability, reduced fuel consumption, increased versatility, or easier maintenance.

In this phase, Hightop also standardizes product platforms, making component reuse and modularity possible. This not only accelerates design cycles but also increases production consistency and enhances long-term serviceability.

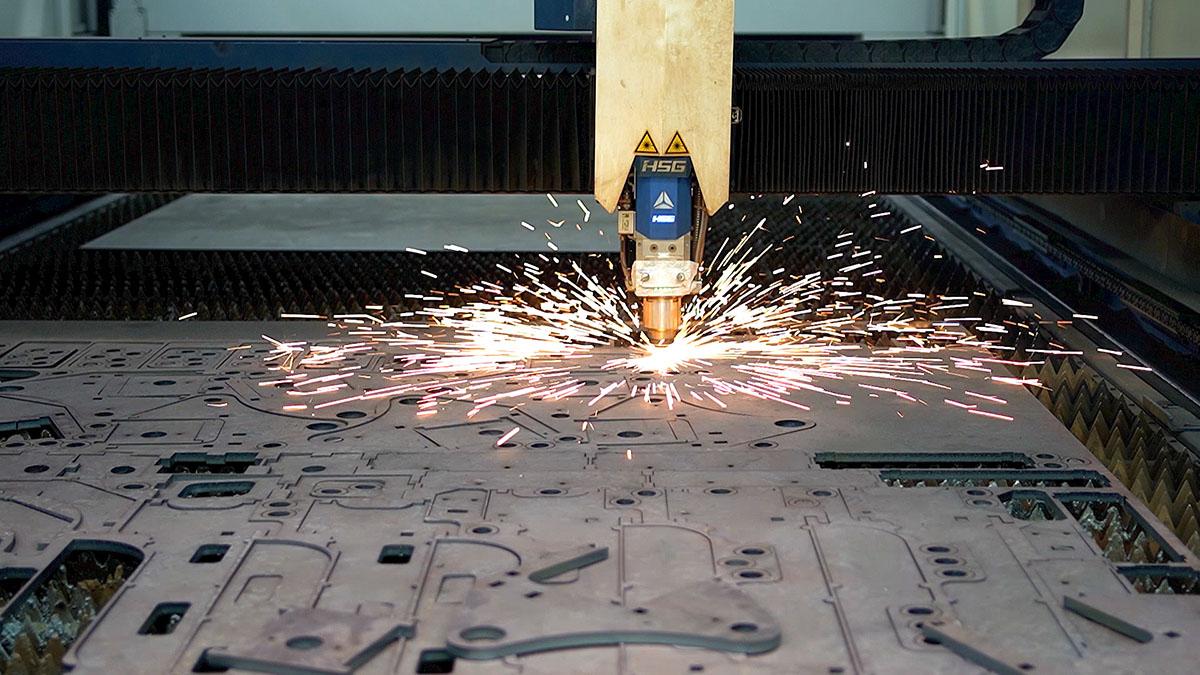

Process 2: Mechanical Processing

In the machining workshop, high-precision laser cutting machines are used to perform batch cutting of sheet metal. This processing method can achieve millimeter-level precision in part processing, ensuring the dimensional accuracy and consistency of each component, laying the foundation for the overall assembly quality of the machine.

The machining process includes cutting, drilling, milling, stamping, bending, and shaping. Each step is controlled by digital equipment such as CNC machining centers, ensuring that tolerance deviations remain within strict standards. By maintaining such precision, Hightop ensures that structural components fit together seamlessly during assembly, minimizing errors that could affect performance or durability.

High-strength materials are selected according to the mechanical stress requirements of different parts. For example, key load-bearing components undergo additional reinforcement treatment to meet industry safety standards. The use of automated feeding systems further improves efficiency, ensuring that the factory can sustain high-volume production while maintaining consistent quality.

In addition, batch processing data is recorded and monitored, enabling complete traceability of every part. This digital record system enhances quality management and provides essential support for long-term after-sales service.

Process 3: Automated Welding

The welding process adopts automated welding robots for operation, and the robotic arm finely completes the welding work of various complex welds. Automated equipment not only improves production efficiency, but also ensures the stability and consistency of welding quality, significantly enhancing the strength and durability of structural components.

Welded structures are among the most critical components of construction machinery, as they directly affect load-bearing strength, fatigue resistance, and long-term stability. Robotic welding ensures even penetration, uniform weld seams, and stable angles, reducing the risk of human-induced inconsistencies.

For structural parts that require additional strength—such as arms, booms, chassis components, and load-bearing frames—Hightop applies multi-layer welding processes and conducts real-time welding temperature monitoring. This ensures that welded joints meet mechanical performance requirements and are capable of withstanding intense operating conditions such as impact, vibration, and continuous heavy-load work.

Quality inspectors perform weld seam testing using visual inspection, ultrasonic testing, and load-stress assessments to guarantee compliance with international manufacturing standards.

Process 4: Surface rust removal

Before spraying, all metal parts must undergo strict rust removal treatment. Through advanced processes such as shot blasting and sandblasting, oxides and impurities on the metal surface are removed to prepare for subsequent surface treatment.

The rust removal process helps metal parts achieve optimal surface roughness, improving coating adhesion and preventing early corrosion in harsh environments. Whether the equipment will be used in humid regions, coastal areas, construction sites, or agricultural fields, rust removal ensures long-term resistance to oxidation and environmental wear.

Hightop controls blasting intensity, speed, and coverage to maintain uniform surface preparation across all parts. After blasting, components undergo secondary cleaning to remove microscopic particles to guarantee a pristine coating surface.

Process 5: Environmental protection spraying

The final process adopts an automated spray coating production line to give the equipment a durable and beautiful "coat". Environmentally friendly powder coating adheres uniformly to the surface of the workpiece through electrostatic adsorption, and forms a sturdy and durable protective layer after high-temperature curing.

Hightop’s powder coating is formulated to resist UV fading, corrosion, impact, and chemical exposure, ensuring that the machine maintains its appearance even after years of outdoor operation. The automated line ensures precise paint thickness, consistent color, and complete coverage of complex structural surfaces.

Environmental sustainability is also prioritized. Powder coatings contain no harmful solvents and generate minimal waste, aligning with international environmental protection standards. Automated curing ovens precisely control heating temperature and duration to ensure the coating forms a long-lasting bond with the metal.

This layer not only enhances visual appeal but also protects against scratches, weather exposure, and harsh working environments.

Process 6: Lean Assembly

In the assembly workshop, experienced technicians assemble various components into a complete machine according to standardized operating procedures. The modular assembly method greatly improves production efficiency while ensuring that each assembly step meets the process requirements.

Each station in the assembly line follows a strict workflow, covering the installation of hydraulic systems, engines, wiring harnesses, tracks, control systems, and cabin assemblies. Torque tools are used to ensure that every bolt and connection meets industry torque specifications.

Lean-production principles guide the assembly process, reducing unnecessary movements, preventing human error, and improving efficiency. Components that require fine adjustment—such as hydraulic lines and electrical connections—are handled by trained specialists to ensure flawless integration.

Before a machine leaves the assembly line, functional tests are conducted, including:

- Hydraulic response testing

- Engine ignition and safety checks

- Walking system calibration

- Structural vibration inspection

- Boom, bucket, and blade motion testing

Through these evaluations, each piece of equipment is confirmed to be fully functional and ready for operational environments.

Process 7: Full process quality inspection

The quality inspection process runs through the entire production process, including three checks: incoming quality inspection, patrol quality inspection, and offline quality inspection. Quality inspectors use professional testing equipment to conduct strict inspections on each component and semi-finished product, requiring all dimensions, performance, and appearance to meet design requirements, and preventing unqualified products from entering the next process.

Incoming material inspection ensures that steel, engines, motors, hoses, cylinders, electrical components, and accessories all comply with supplier standards and Hightop’s internal benchmark requirements. During production, patrol inspectors monitor machining accuracy, welding integrity, coating uniformity, and assembly correctness.

Finally, each completed machine undergoes a comprehensive offline inspection, including stability testing, functional testing under load, hydraulic leakage checks, and safety verification. Only equipment that passes all checkpoints can be packaged and shipped.

Through the meticulous craftsmanship of these seven processes, each Hightop device embodies the ingenuity and wisdom of its manufacturer. Rigorous process flow, advanced production equipment, and experienced technical team jointly ensure that every factory product meets high quality requirements. Hightop Group has gained widespread recognition and a good reputation in the global market through strict control over every aspect of production. In the future, Hightop Group will continue to optimize its production and manufacturing processes, create greater value for global customers with outstanding product quality and a comprehensive service system.

If you have any suggestions or question for us.Please contact us.